Burn Off Ovens for Plastics, Fiber & Chemicals

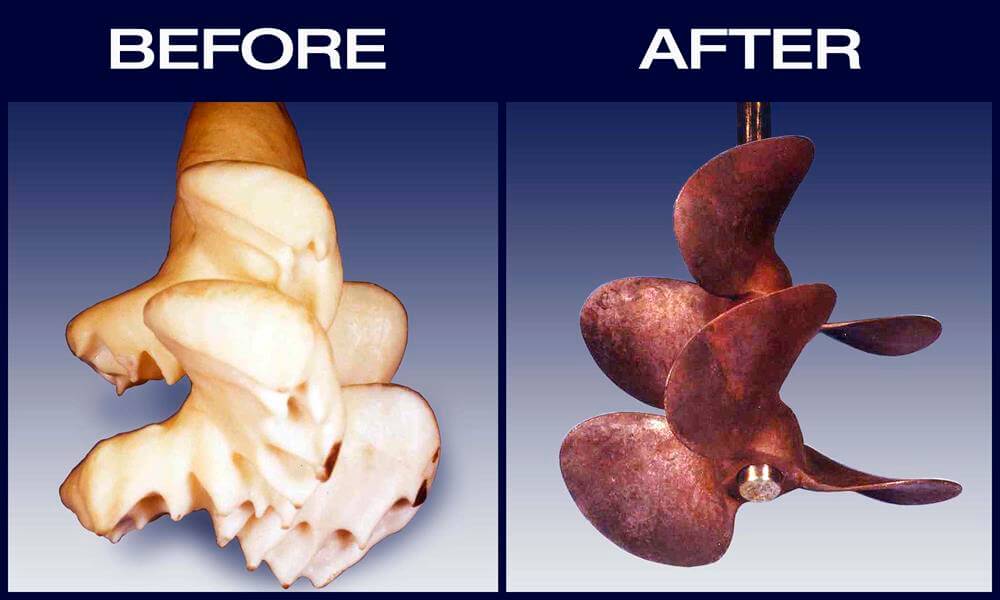

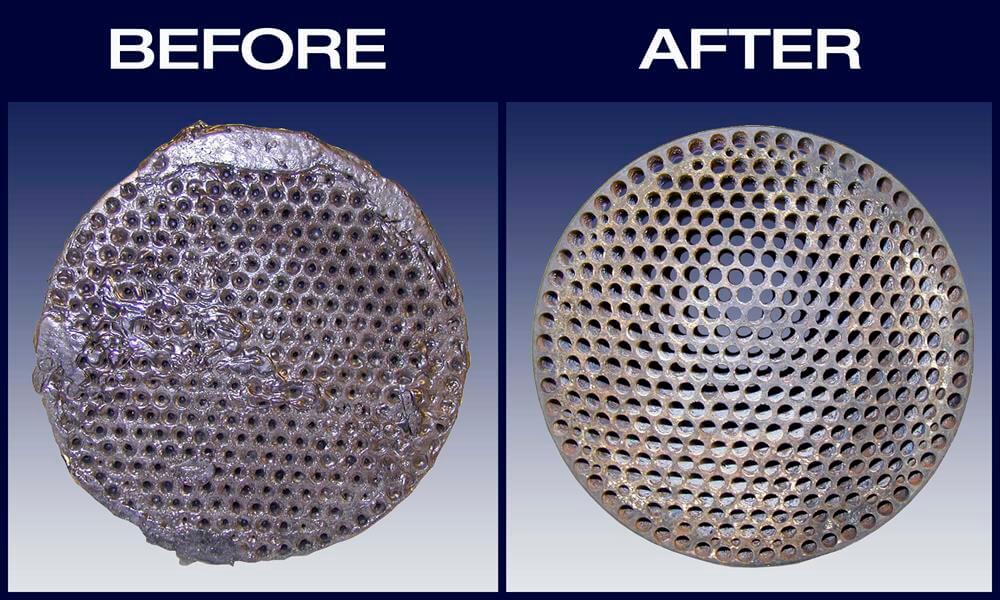

Pollution Control Burn-Off Ovens safely remove polymer buildup on expensive dies, molds, extrusion screws, breaker plates, and other metal parts used in plastics, fiber, and chemical processing operations. Burn-Off Ovens eliminate the use of abrasives, solvents, and chemicals and their health and environmental risks. Below is a common application scenario for our industrial burn-off ovens.

Why Use A Burn-Off Oven to Remove Plastics, Fiber & Chemicals Coatings?

Today's plastics, fiber, and chemical manufacturing environments must maintain rigorous quality standards to stay competitive in the marketplace. This requires that tools, parts, and equipment are operating at peak efficiency so that production lines are pristine. Changes in process materials or colors, the build-up of polymers or simply routine maintenance requires that equipment be thoroughly cleaned before it is returned to production.

Repetitive manual cleaning with abrasives and chemicals will in time result in physical damage, not to mention injury to employees. Chemicals and abrasives may also have serious health and environmental consequences.

Burn-Off Oven Solution for Plastic Removal

Pollution Control's InertGas™ Cleaning Furnace (Burn-Off Oven) was designed by a polymer chemist and is manufactured specifically for the removal of polymers. Virtually pollution-free, it's patented Controlled Pyrolysis® process eliminates the use of chemical strippers and other toxic materials. The InertGas™ industrial oven evenly distributes the temperature in the cleaning chamber allowing polymers to flow to a secondary collection chamber for easy removal and disposal.

Pyrolysis is a gentle process that extends the life of parts and tooling. It safely removes polymers by vaporizing contaminants into smoke. The smoke is then burned in an afterburner completely consuming all pollutants leaving only invisible, odorless, and harmless water vapor and carbon dioxide. The oven's easy-to-operate and self-adjusting control system reduces labor costs, machinery downtime, and any risk of damage to parts. Automatic time cycles ensure the oven runs only long enough to clean parts.

PLASTICS, FIBER, & CHEMICAL PDF RESOURCES

- Extruder Screw Cleaner

- Plastics Fiber IGG Standard

- IGG 27F & IGG 52 Burn-Off Oven

- IGG SP-13 Cleaning Oven

Benefits of our Plastic Removal Furnace

| Designed by a Polymer Chemist | Safely removes polymers, adhesives and chemicals from extrusion screws, breakers, plates, dies, nozzles and other metal parts |

| Safe and Easy to Operate | Diagnostic Panel fully monitors and displays 15 operating functions |

| Safe and Gentle Process | Carefully reduces oxygen at the point of polymer decomposition and then increases the atmosphere to eliminate carbon residues |