Burn-Off Ovens for Oil & Gas Industry

Pollution Control Burn-Off Ovens, also known as burn out ovens, have been an integral part of the operational and regulatory concerns of the oil and gas industry since our beginnings in the early seventies. The industry discovered that investing in burn-off ovens saves money, extends the life of tools and equipment, improves production efficiency, and reduces the waste stream.

Download Oilfield Parts Stripping PDF

Why Use A Burn-Off Oven for Oil & Gas?

In the Oil & Gas industry, oilfield parts reclamation and remanufacturing operations must answer critical questions when considering industrial cleaning techniques and equipment because it is vital to their manufacturing effectiveness and capacity:

- Is it safe?

- Is it cost effective?

- Does it enhance quality and capacity?

- What is its "waste stream?"

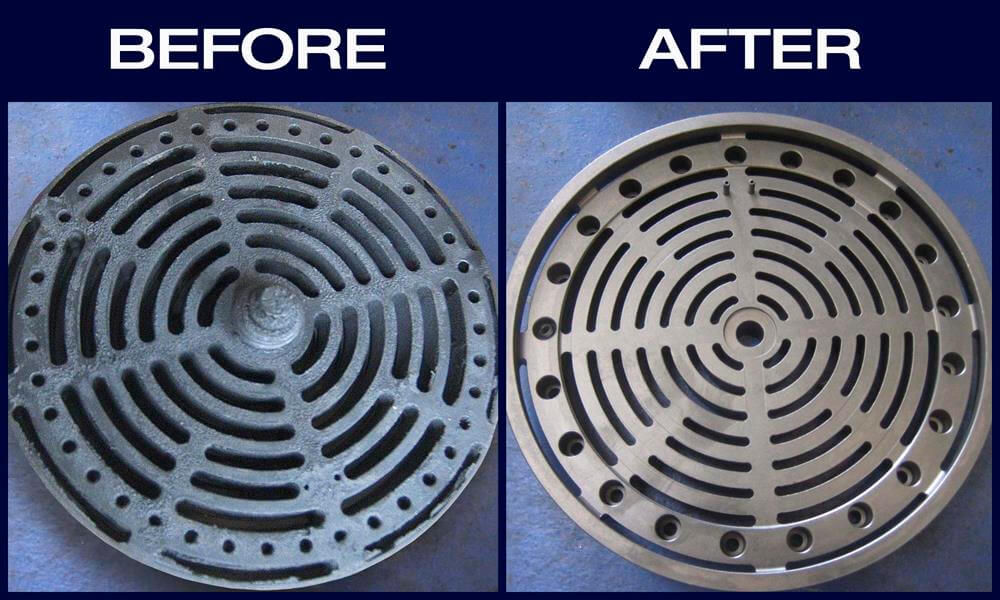

Every part, tool, and piece of equipment used in the production of oil and gas usually does its job in very harsh conditions and it’s usually “fouled” with unwanted accumulations of the byproducts of oil and gas production – oil, grease, scale, paraffin, polymers, chemicals, paint, corrosion, etc. Heat exchangers, compressors, turbines, and pumps are some of the most vital pieces of equipment used in the oil and gas industry. Cleaning and reclaiming these parts using abrasive manual techniques such as torches, brushes, sanders, and drills are slow and expensive and, in time, will damage parts and risk of injury to employees. Similarly, the use of chemical strippers and other toxic agents pose serious safety, health, and environmental concerns and they significantly contribute to the waste stream.

Burn-Off Oven Solutions

PCPC's Controlled Pyrolysis® Cleaning Furnace (Burn-Off Oven) is safe, easy to operate, and virtually pollution-free. It safely removes oil, grease, sludge, epoxy, polymers, paint, and other organic materials common in the waste steam of oil and gas production and that may accumulate on and “foul” oilfield parts and equipment. Additionally, PCPC Burn-Off Ovens eliminate other substances from the waste steam commonly used to clean and reclaim oilfield parts and machinery such as chemical strippers, solvents, and other toxic agents.

PCPC Burn-Off Ovens clean by the process of pyrolysis – which is the chemical decomposition of organic material through the action of heat. No flames ever touch the parts or enter the cleaning chamber during processing. Organic materials on parts are vaporized into smoke leaving only small amounts of ash that is easily rinsed away with water. The smoke driven off during cleaning is then vented through an afterburner which completely consumes any remaining pollutants leaving only invisible, odorless, and harmless water vapor and carbon dioxide to exhaust into the atmosphere.

Benefits of our Oil Parts Stripping Solution

| Reduces the Waste Stream | It's pollution-free process safely and efficiently removes grease, paint, carbon and other combustibles from oilfield parts, equipment and tooling |

| Reduces Cost & Equipment Downtime | Controlled Pyrolysis® reclaims and extends the life of oilfield parts and equipment |

| Labor-Saving, Safe & Effective | Automated push button controls and processing guarantees parts come out of the oven dry and ready for rinse or shot blasting |

OILFIELD PARTS STRIPPING PDF RESOURCE