Industrial Burn-Off Ovens

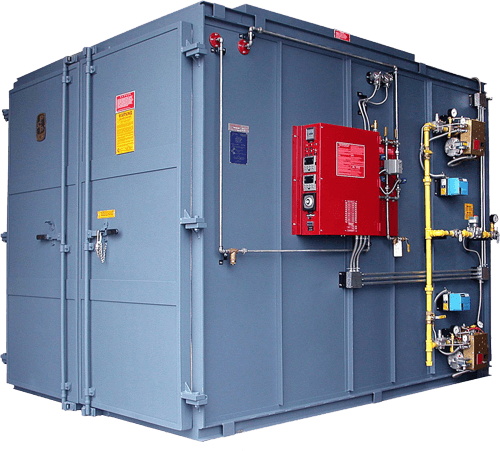

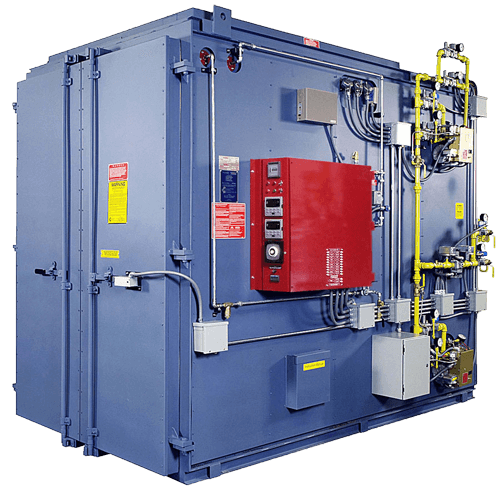

At Pollution Control Products Co., you can select the precise burn-off oven and industrial furnace model to best handle your cleaning and stripping needs. Since 1971, we have manufactured successful burn-off ovens for a wide range of industrial cleaning oven applications.

What are Burn Off Ovens?

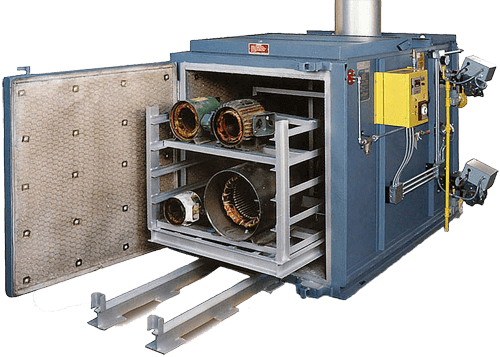

Burn off ovens, also known as burn out ovens, are designed to safely and efficiently remove baked-on coatings from many different types of parts. Industrial burn off ovens are well suited for a variety of applications including auto-parts and engine rebuilding, plastics, fiber & chemicals, electric motor rebuilding, and more.

How Do Burn Off Ovens Work?

Burn-off ovens have five primary functional components that have their own unique purpose. On our furnaces, the primary heat input burner fires into a combustion chamber, which contains the flame, so that only heat is discharged into the work area containing the parts. No flame actually contacts the parts. Other than the air required for combustion of the input burner fuel, no additional air is added to the furnace.

Therefore, the oxygen content within the furnace is reduced to a level that prevents the material from catching on fire. The heat causes the organic material to decompose into vapors and pyrolysis gases which are then processed in a secondary direct-flame afterburner. See a diagram of the process here.

Burn Off Oven Types

We make four types of industrial burn-off ovens to cover the entire field of thermal stripping and cleaning:

Materials

A burn off oven, also known as a heat exchanger cleaning furnace, can be used to remove different types of materials from various parts. Some of these materials include:

- Paint

- Powder Coating

- Epoxy

- Oil

- Urethane

- Plastic

- Grease

Applications

For over 45 years, PCPC has been a leader in manufacturing industrial burn-off ovens for a wide range of different applications. For this reason, we understand that reliable and precise burn off ovens are vital to your business.

Below are the different applications we have manufactured ovens for:

- Paint & Powder Coating

- Plastics, Fiber & Chemicals

- Electric Motor Rebuilding

- Auto-Parts and Engine Rebuilding

- Oil & Gas

- Engine Rebuilding

- Commercial Cleaners

- Reclaiming Diesel Particulate Filters

- Rubber Removal

- Custom Appilications

In addition, our burn-off ovens can handle removing paint from many different products and parts. Some of these parts & products include:

- Racks

- Fixtures

- Fractional Horse-Power Stators

- Power Station Transformers

- Paint Hooks & Hangers

- Car Skids & Grates

- Engine Blocks

- Water Pumps

- Breaker Plates

- Extruder Screws

Industrial Ovens Features

Our industrial ovens are included with a wide range of features to accomplish your specific needs.

Our unique features include:

- Patented Controlled Pyrolysis® Water Spray System controls the rate of smoke emissions preventing damage due to ignition or over-heating in the furnace.

- The Primary Burner heats the cleaning chamber to 800°F (427°c). Volatile materials are driven off as smoke. The burner flame is confined to the combustion chamber never touching the parts.

- The Afterburner operating at 1400°F (760°C) for half second burns the smoke, consuming the pollutants, leaving only invisible, odorless and harmless water vapor and carbon dioxide to exit the exhaust stack.

- Explosion Relief Door(s) automatically opens to relieve excess pressure then closes preventing air from reaching combustible materials.

- Fully Automated Controls include Diagnostic Panel indicator lights reflect the operational status of the oven and its controls. Indicator light failure pin-points the problem.

Benefits of PCPC Burn-Off Ovens

Pollution Free

PCPC Burn Off Ovens are pollution-free, eliminating the use of acids, solvents and other hazardous cleaning materials. During the Controlled Pyrolysis® process, smoke, driven off during cleaning, is consumed in a powerful afterburner leaving only invisible, odorless and harmless carbon dioxide and water vapor to exhaust into the atmosphere.

Extend Service Life

PCPC Burn Off Ovens extend the life of tools and parts! Parts come out clean and ready for reuse or rework with a minimum of preparation. Cost savings will usually pay for the furnace in a short time and continue to pay dividends year after year. Proven in over 8,000 installations worldwide.

Automated, Labor Savers

PCPC Burn Off Ovens are fully automated and labor-saving! Our unique furnace design, advanced diagnostics and "push button" automated control system positively manage the charring of the materials and the rate of emission of smoke and other volatiles inside the furnace. Excess temperature is automatically controlled with water injection eliminating any danger of damage to parts.

Fuel Efficient

PCPC Burn Off Ovens are fuel-efficient, safe, and built to last! Space-Age high-temperature soft ceramic fiber insulation and other fuel-efficient features allow the use of burners firing as little as 150,000 BTU per hour to quickly heat the parts and burn the smoke.

Want to see for yourself? Try a free test cleaning!

Why Pollution Control Products Company?

At Pollution Control Products Co., you can select the precise burn-off oven and industrial furnace model to best handle your cleaning and stripping needs. Since 1971, we have manufactured successful burn-off ovens for a wide range of industries and applications.

Pollution Control Product Co. is a trusted burn off ovens manufacturer. Since 1971, our company has manufactured and installed over 8,000 burn-off ovens worldwide. Our burn off ovens are reliable and equipped with the latest technology. We build furnaces based on our customer's needs, and we are ready to help you with your next project.

Want to learn more about our industrial burn off ovens? Contact us today!

Click here to Request A Quote

or call us today at 214-358-1539